Modular Homes

Reset filter

Reset filter Installed houses

Modular Construction Advantages

In comparison to more traditional brick and foam block houses Individual layout

Individual layout

Individual layout development based on the request of the customer, according to the chosen size of the house

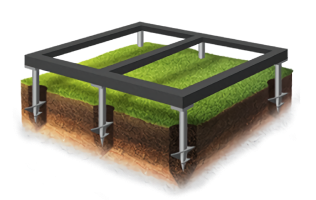

The possibility of installation on the pile foundation

The possibility of installation on the pile foundation

The possibility of installation on the pile foundation, which speeds up the process and lowers the cost

Modular manufacturing technology

Modular manufacturing technology

We manufacture modular houses, turnkey, 2-3 months after contract signing

Frequently asked questions / FAQ

answers to the most common questions when choosing modular homesA modular house is a construction technology in which sections of the house are made of wooden beams and metal. The house is manufactured at the factory and delivered ready-made to the customer on a previously prepared plot.

The equipment of the house allows for a comfortable stay during winter. The energy efficiency of the house has high performance, which allows you to warm it up with less heat than would be used in the same area in a standard house.

Frame houses are assembled on the customer’s site, as opposed to modular homes, which are directly put together at the factory.

Yes, it is possible to register in the modular house.

Yes, a modular house is installed on the foundation solely. It adds stability to a modular home.

The frame of a modular house is made of wood with insulation inside of it, and it is closed with a vapor barrier from two sides. On the outer side of the frame, the OSB plate with a metal panel or façade wood attached to it is sewn up. On the inside, either timber with a wooden façade or plasterboard is attached, and it can be used for paint jobs in the future.

Yes, the modular houses from Unitbud are equipped with noise-canceling materials.

Only high-quality materials are used in the construction of the house, so there won’t be any shaking. You can not only walk around the house but even run )

For the modular house frame, only chamber-dried wood is used. After the drying process, it is shaped on 4 sides to establish the accurate geometry (all of the boards are the same). After these processes, the wood becomes smooth and dry.

Yes, every house has underfloor heating installed over the entire area. Therefore, the floor is always warm.

All of the wood is treated with mildew protection. Also, we don’t have a single element of the façade or roof, that would let moisture through resulting in mold and mildew.

Yes, the ventilation is efficiently worked-out. If so desired, it is possible to install a recuperator and additional ventilation.

Each house has a heat pump that will be heating the building. There is underfloor heating installed in the bathrooms, as well as in the whole house, it helps to maintain the heat in the house. If so desired, you can install electric convectors which will heat the house additionally. Also, with large houses, the fireplace is included as a gift (only where it is intended)

During the construction of a modular house, a pile foundation is used. It makes it possible to classify a modular house as a temporary installation, which doesn’t need to be registered. However, if there is a request, we can provide all the necessary documents for full registration of the house at your sole discretion.

Modular houses: what are they and why are they popular?

The old belief, which states, that every man in his life should build a house by himself, can be forgotten. Modern residential buildings are technologically complex, require heavy machinery use, and can not be put up singlehandedly. A busy person does not have time to wait for months and years for a home to be built, so modular houses are in high demand. The modules are manufactured and sold by Unitbud.

Definition of a modular home

Technologies can significantly increase the speed of construction by eliminating wet processes. Concrete, glue, plasters, mastics – all these things take weeks to dry, preventing construction work from continuing. Meanwhile, the individual building blocks can be connected by bolts or pre-provisioned grooves and bearing connections, making the assembly as simple as putting together a construction set under standard drawings. In total, a ready-made modular house appears on a prepared site a month after the decision to build it was made. Hence, the definition of a modular structure is a prefabricated building made of standardized parts which are assembled into a single unit at a factory workshop following a standard design. On-site suppliers can combine several modules into a larger building.

The attribute of a ready-made modular house is its immediate ability to accept residents. Although utility communications aren’t included in the “details” set, the project reckons for them. As a rule, no finishing work is required – the interior and exterior panels have had an aesthetic appearance from the very beginning. By purchasing a modular home, the family saves not only time but also money

Advantages of houses made of modules

There are many reasons why you should buy a modular house – let’s list them.

- The lightweight structure does not require an expensive tile foundation and does not spoil the original landscape; it can be installed anywhere, and you can even move the fixture with you. A permit isn’t needed for modular building construction in Ukraine.

- People and things inside the module are reliably protected from cold temperatures. Construction of modular buildings in Ukraine is done with the use of energy-saving materials designed for our climate.

- The house is built (assembled) at a factory, not on a site, without disturbing neighbors or households. It is put together at the specified location in one day.

- The most popular models of such houses are usually available in the warehouse in finished form. Once you’ve paid the cost of a modern modular home, it is possible to get comfortable housing in just a few days.

- Although the building is built accordingly to a standard project, the selection of such projects is huge. Thanks to this, every family can buy housing according to their needs. If it is necessary, specialists can create an individual project of a modern modular building at a cost lower than that of a similar standard structure.

- Given the cost of housing in most regions, buying such a house is economically justified. The price of a modular house in Kyiv is especially favorable – if you compare it with the prices of apartments and mansions, the difference will be huge.

- Investing in a mansion made of modules is a liquid investment because the building lasts for decades. Once it is realized how much secondhand modular housing costs, the owner understands that the house can be resold profitably in the future.

Production Stages

The answer to the question of why modular housing costs so much, lies in the efficiency and high construction speed. They look like this:

- select a standard project or create an individual one;

- foundation works are underway;

- The plant assembles the frame and finishes it in the shop;

- utilities are being installed on the site;

- the assembled modular house is delivered to the specified address and installed.

Unitbud is ready to produce a modular house suitable for year-round living on a turnkey basis. The customer’s objective is to agree on the project, provide the delivery address, pay the full price of the order, and wait. The managers will inform you of the exact date of arrival of the finished building at the site, and just in a few weeks you will become a happy owner of your own home!

Call back

Call back